Datasheet - smart Relay Monitoring System

Engineered solutions

smart Relay Monitoring System

Railcar builders have been using relays to control equipment for years. During train maintenance, relays and devices such as lamps, door push-buttons or else are often exchanged before their end of life or when they are no longer working. Moving from schedule-based to condition-based maintenance saves significant maintenance costs for train operators.

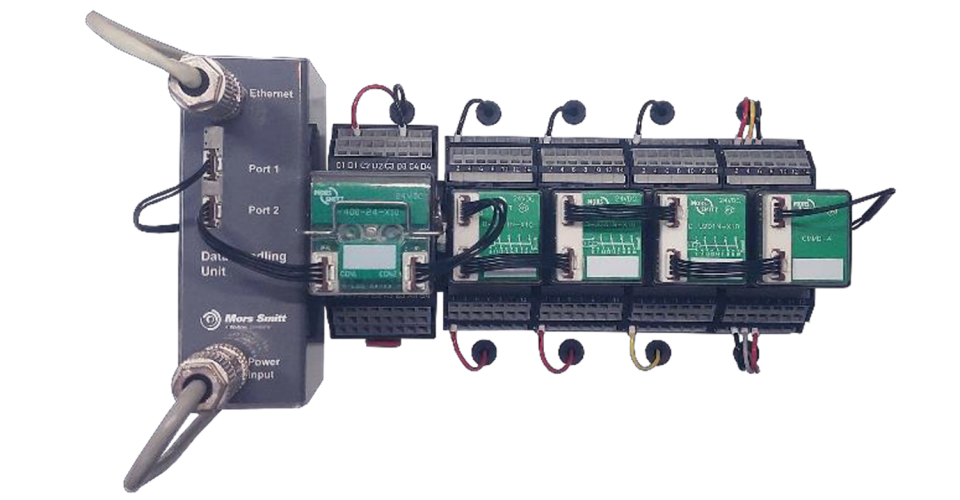

Mors Smitt™ smart Relay Monitoring System is developed to analyze the condition of relays and connected devices in real-time and identify the accurate timing for part replacements. The result: reduced service costs and increased train control availability.

To enable predictive maintenance system includes:

- Voltage Measurement Module (VMM) to monitor the voltage per relay contact

- Current Measurement Module (CMM) to monitor the current per relay contact

- Data Handling Unit to connect up to 50 relays/devices (daisy chaining possible):

- Seven days of data storage capacity

- Serial bus configuration allows DHU, connected relays and modules to communicate with each other

- Data output are easily exportable to the train control management system or other computer devices in a variety of formats (.CSV, .SQL).